Economic factures dictate the need for high reliability and uptime in power generating wind turbines. The wind turbines electrical generating system employs a variety of technologies depending on the manufacturer. There are the typical asynchronous machines, where there is often two generators employed in a single turbine. A larger one for higher and a smaller generator each designed to operate at the higher and lower wind speeds. These are usually directly coupled to the grid via a transformer. There are also permanent magnet brushless generators that will indirectly feed the grid via a converter drive. All the electrical systems above are constantly exposed to excessive vibrations, wear and tear and hazards. Based on their constructive nature, lightning strikes are also a huge problem. Bender mitigates the risk associated with these issues by employing a variety of ground fault detection, insulation monitoring and fault location units in these demanding environments. Unplanned downtime and time consuming fault location issues will be reduced to a minimum.

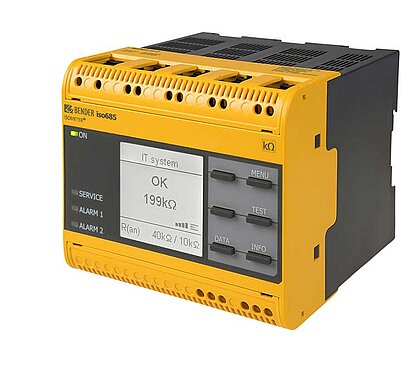

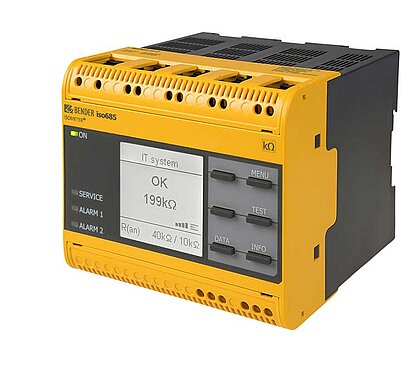

Power for a wind turbines controls and operation are usually being fed from an external source. The feed to the turbine should be monitored at all times for its electrical integrity since losing the source will render the revenue producing turbine inoperable until the problem is fixed. Benders ground fault monitoring systems ensure that the supply to the turbine is constantly protected and supervised for electrical breakdown situations.

Alternative energy sources feed in points must be constantly monitored and switched off in case the main power grid drops off. This practice is known as anti-islanding protection. The Bender VMD460 relay series checks whether frequency and voltage limits are within range. Additional features such as ROCOF (Rate of change of frequency) and vector jump recognition are added to ensure a proper alert to a missing grid. The three phase VDM460 relay comes with preconfigured setting to fulfill the relevant standards such as IEEE1547 but can also be configured via menu by the touch of a button.

Pitch control systems are vital for operating a wind turbine at its maximum peak power output. electrical faults can render the pit control useless which will result in the turbine getting stuck at a certain pitch, or worse may even stall the turbine and drive its output to zero until the problem is fixed. Bender RCMS ground fault monitoring systems constantly record such a systems electrical leakage towards the turbines chassis. Once the preset thresholds have been breached, the system alerts the personnel as to the level and the exact location of the problem.

Azimuth or yaw control systems are gear drive systems designed to direct the wind turbine towards the wind, or in very extreme conditions, may even direct the turbine out of the wind. The system usually consists of a wind direction sensing vane, coupled to a gear drive and electrical motors. A ground fault in the azimuth control can disable the turbines “sense of direction” and will pretty much render it unproductive. Benders RCMA and RCMS ground fault monitoring units will sense an electrical failure at very low levels and alert personnel before the situation worsens.

Bender's COMTRAXX gateways communicate the insulation and ground fault values from the wind power plant via Ethernet/TCP-IP or Modbus to the higher level supervisory systems or the operators for a clear concise picture of the overall turbines electrical health.

| Name | Category | Size | Language | Timestamp | D-/B-Number |

|---|---|---|---|---|---|

| Product Overview ISOMETER®/ISOSCAN® | Product Overviews | 5.3 MB | EN | 2024/02/1616.02.2024 | |

| Product Overview - Residual Current Monitoring | Product Overviews | 4.2 MB | EN | 2026/02/1111.02.2026 | |

| Renewable Energies | Market Segment Brochures | 3.6 MB | EN | 2025/04/0303.04.2025 | |

| Insulation Fault Location - Planning and Setup | Technical Article | 112.4 KB | EN | 2019/05/1313.05.2019 | |

| Safe Connection to the Grid VMD460-NA | Flyers | 222.0 KB | EN | 2019/05/1313.05.2019 | D00001 |

| Answers for Tomorrow | Technical Article | 764.8 KB | EN | 2019/05/1313.05.2019 | |

| Electrical Safety in Control and Auxiliary Circuits | Technical Article | 632.6 KB | EN | 2023/04/2121.04.2023 |

Products

![[Translate to North American English:] COMTRAXX® COM465IP](/fileadmin/_processed_/f/d/csm_COM465IP_01_WEB_296d1e7f5c.jpg)

Condition Monitor with an integrated gateway for the connection of Bender devices to Ethernet-TCP/IP networks

Ground-fault detector for ungrounded AC/DC systems

Ground-fault locator for localization of ground faults in control circuits

Ground-fault location module for ungrounded AC/DC systems

Ground-fault locator with 6 integrated measuring current transformers for localization of ground faults in main circuits

Ground-fault locator with 6 integrated measuring current transformers for localization of ground faults in control circuits

Portable ground-fault location systems for ungrounded and grounded systems

Multi-channel AC/DC ground-fault monitor

Multichannel AC, pulsed DC and AC/DC sensitive ground-fault monitor

Multi-channel AC/DC ground-fault monitor with individual relay outputs

Multichannel AC, pulsed DC and AC/DC sensitive ground-fault monitor with one alarm contact per channel

Network and system protection (NS protection) for monitoring the power infeed of power generation systems

![[Translate to North American English:] COMTRAXX® COM465IP](/fileadmin/_processed_/f/d/csm_COM465IP_01_WEB_296d1e7f5c.jpg)

Condition Monitor with an integrated gateway for the connection of Bender devices to Ethernet-TCP/IP networks

Ground-fault detector for ungrounded AC/DC systems

Ground-fault locator for localization of ground faults in control circuits

Ground-fault location module for ungrounded AC/DC systems

Ground-fault locator with 6 integrated measuring current transformers for localization of ground faults in main circuits

Ground-fault locator with 6 integrated measuring current transformers for localization of ground faults in control circuits

Portable ground-fault location systems for ungrounded and grounded systems

Multi-channel AC/DC ground-fault monitor

Multichannel AC, pulsed DC and AC/DC sensitive ground-fault monitor

Multi-channel AC/DC ground-fault monitor with individual relay outputs

Multichannel AC, pulsed DC and AC/DC sensitive ground-fault monitor with one alarm contact per channel

Network and system protection (NS protection) for monitoring the power infeed of power generation systems

Windenergieanlagen - Teil 2: Anforderungen für kleine Windenergieanlagen

Regola tecnica di riferimento per la connessione di Utenti attivi e passivi alle reti AT ed MT delle imprese distributrici di energia elettrica (Reference technical rules for the connection of active and passive consumers to the HV and MV electrical networks of distribution Company)

Selbsttätige Schaltstelle zwischen einer netzparallelen Eigenerzeugungsanlage und dem öffentlichen Niederspannungsnetz (Norm wurde zurückgezogen und durch DIN VDE V 0126-1-1 ersetzt)

Anwendungsregel:2011-08 Erzeugungsanlagen am Niederspannungsnetz Technische Mindestanforderungen für Anschluss und Parallelbetrieb von Erzeugungsanlagen am Niederspannungsnetz

Specifieke technische aansluitingsvoorschriften voor gedecentraliseerde productie-installaties die in parallel werken met het distributienet

Recommendations for the Connection of Generating Plant to the Distribution Systems of Licensed Distribution Network Operators

Recommendations for the Connection of Generating Plant to the Distribution Systems of Licensed Distribution Network Operators

Recommendations for the Connection of Type Tested Small-scale Embedded Generators (up to 16A per phase) in parallel with Low Voltage Distribution Systems

Recommendations for the Connection of Type Tested Small-scale Embedded Generators (up to 16A per phase) in parallel with Low Voltage Distribution Systems

Ausrüstung von Starkstromanlagen mit elektronischen Betriebsmitteln

Messrelais und Schutzeinrichtungen - Teil 127: Funktionsnorm für Über-/Unterspannungsschutz